Top 5 PLC Courses to Learn Online To Improve Your Industrial Automation Skills

Custom software is the optimal solution for ensuring functionality and usability for your unique company demands. Custom software creation, on the other hand, is not limited to typical desktop software programmes. Computers are used extensively in modern business to manage anything from automation to networking. Regrettably, finding suitable control system solutions is frequently challenging. While the contemporary industry has a variety of specific requirements, it places a high premium on the control system itself. A standard desktop computer is incapable of meeting all of these requirements. That’s where PLC courses come into the picture.

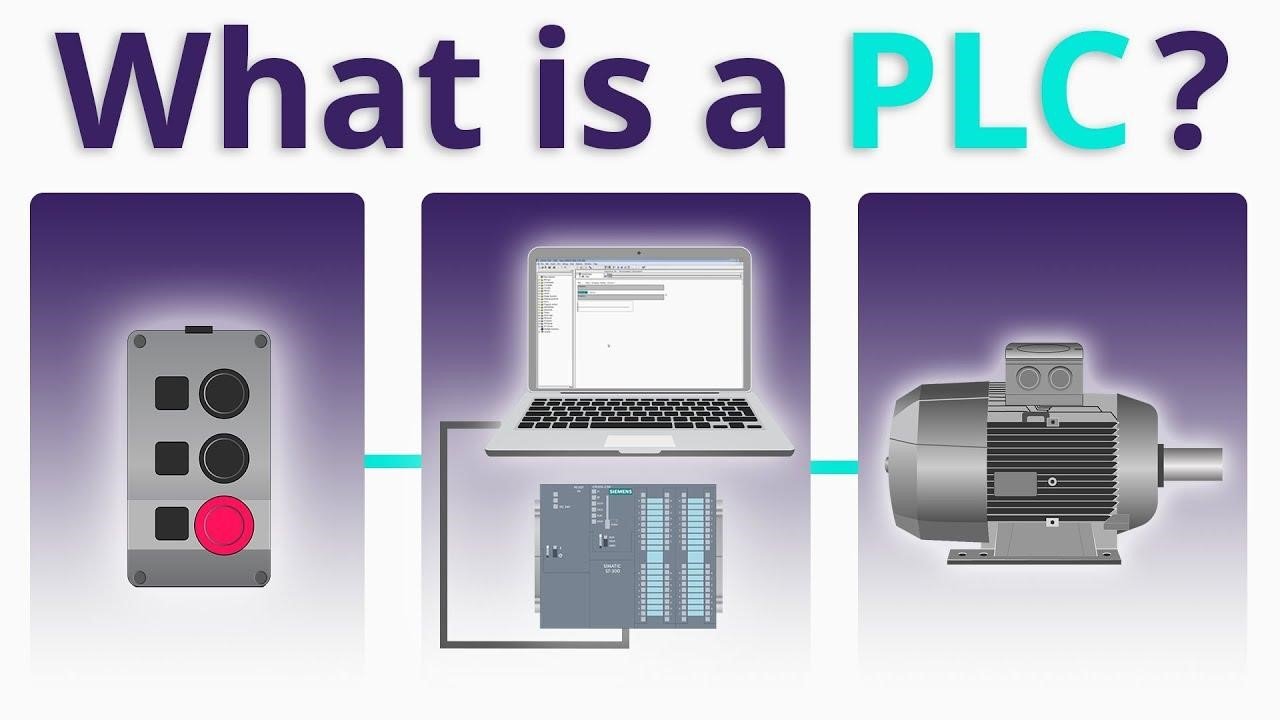

A PLC, or Programmable Logic Controller, is a type of control system that makes use of user-defined commands to regulate the input and output of numerous devices. Due to its versatility, it’s an excellent tool for applications. Since user commands determine how the system directs output devices, PLC industrial automation may be used in virtually any application.

You may take up industrial automation with a PLC course to learn everything about it and start your career in this field. Here we will learn about why PLC is so important and the top courses available for you to learn PLC.

What is the difference between SCADA and PLC in Industrial Automation?

A programmable logic controller (PLC) is a type of controller that is utilized in industrial automation applications. It is used to regulate the operation of a variety of machinery, including motors, pumps, valves, and servomotors.

PLCs are intended to be programmed remotely. They may be programmed in a variety of ways using a variety of programming languages and tools. Ladder diagrams, C, and LabVIEW are just a few of the programming languages available.

PLCs are designed to respond quickly to changes in speed or direction in industrial applications. Additionally, they can handle high-speed inputs while giving accurate, low-latency, and high-bandwidth outputs.

PLCs are ideal for producers since they are designed primarily for industrial tasks. Control systems perform well as automation controllers in robotic manufacturing activities. Additionally, they provide a more orderly computing solution than limitless relays and timers, allowing manufacturers to trace faults more easily.

SCADA is an acronym for supervisory control and data acquisition. A supervisory control and data acquisition system is a type of computer system that is used to monitor and manage industrial automation systems. Industrial automation systems are used to monitor and regulate the operation of machinery in factories, water treatment plants, power plants etc.

SCADA is most often associated with Industrial Automation Systems, although it may also be utilized in other domains, such as monitoring building infrastructure or controlling energy supply. SCADA enables the automation of large-scale industrial equipment operations by allowing remote access to data collected from multiple sensors around the region and consolidating it into a single database that can be accessed.

PLC and SCADA systems are becoming increasingly important in industrial automation.

Top Industrial Automation With PLC Courses

1. LearnVern

PLC SCADA for Industrial Automation is a comprehensive course taught in Hindi by instructors with years of industry experience. This PLC SCADA Training Course covers all you need to know to become a master PLC SCADA programmer. If you’re interested in starting a career as an Automation Engineer or PLC Programmer.

The PLC Industrial Automation Training programme is designed to provide students with the ideal step-by-step learning experience necessary to obtain a job.

You will get new skills:

- Acquaint yourself with the ideas behind industrial automation.

- Acquire a working knowledge of PLCs.

- The fundamental ideas underlying supervisory control.

- Recognize the many types of networks.

This course is suitable for an introduction to Industrial Automation using PLC programming. It is geared toward individuals interested in pursuing careers as automation engineers or technicians.

2. Tops Technologies

This PLC programming training session equips participants with the information, know-how, and technical skills necessary to operate with a variety of PLCs.

The software offers instruction using the PLCLogix 500, a controller simulator that emulates Rockwell Logix 500 controllers. This self-paced programme enables students to progress through high-quality programme content that is separated into distinct modules and includes text, animations, and audio lectures. PLCLogix 500 enables learners to replicate a range of applications through the use of more than 250 pre-built lab projects and ten interactive 3D animations.

You will get the following skills:

- Create PLC programmes from the ground up.

- Distinguish between digital and analogue signals.

- Acquaint yourself with fundamental, industry-standard control approaches.

- Acquire a working knowledge of alarms and alerts.

3. University of Buffalo

Manufacturers are increasingly relying on tools that understand their own states and the condition of their surroundings – and are capable of making judgments about machine activity processes.

This is referred to as intelligent machining, and students will learn about its history, tools, and associated terminology in this course. Discover how the integration of smart sensors and controllers contributes to productivity gains.

You will become familiar with a variety of sensors and sensing techniques, process control strategies, and open architecture systems that may be used to allow intelligent machining. This training will equip you to work on intelligent machining projects. The course’s major themes will be conveyed through lectures, conversations, readings, and a variety of videos.

4. IPCS Automation

Individuals interested in developing their skills in PLC programming should strongly consider this session. You will learn about PLC application projects, micrologix 1000, HMI connectivity, and industrial sensors as part of this course.

You may also include the PLC Programming certificate on your LinkedIn profile.

You will acquire the following skills:

- Acquire knowledge about ladder logic programming.

- Concepts of PLC wiring.

- How to conduct a productive troubleshooting session.

This course is designed for programmers, engineers, and technicians who work with PLCs.

5. Training in PLC Programming (EEP)

While this is not a true course, EEP has compiled YouTube videos into a comprehensive learning experience on PLC programming. You will learn about the basics of ladder logic and PLC programming.

The course is split into two halves. The first section teaches you about the fundamentals of programming a programmable logic controller (PLC). This section will teach you everything you need to know about PLCs and PLC ladder logic programming. The second section is devoted entirely to Allen Bradley PLCs.

If you wish to further your PLC programming training, this is a good course, to begin with.

Salary

PLC Programmer salary in India ranges between ₹ 1.2 Lakhs to ₹ 6.6 Lakhs with an average yearly income of ₹ 3.0 Lakhs.

Conclusion

PLCs are always improving to become the finest alternative for a wide array of industrial automation applications. The scope of plc programming is continuously expanding because of increased programming flexibility and convenience, scalability, more memory, extremely high-speed (gigabit) Ethernet, and integrated wireless functionalities.

PLCs benefit from USB technology, making it easier to connect to the Internet, configure, and monitor your control systems. PLC programming will change, and when smaller micro and mini-USB ports become available, you should expect to see this option on a greater number of smaller PLCs. PLCs will continue to change in the future as communications, hardware, and software technologies advance.

The demand for PLC programmers is on the rise, and anyone who starts a career in this field right now is set for a bright future ahead.